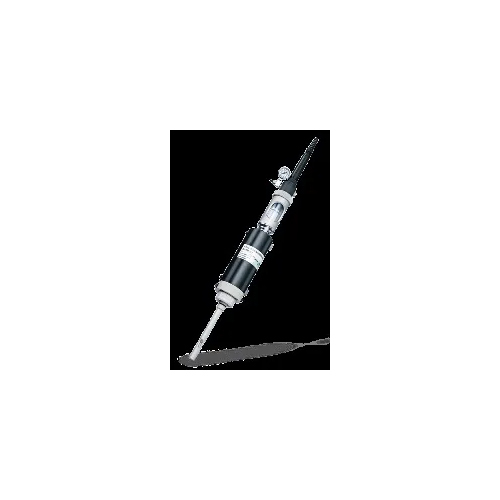

Online ph analyzer

Product Details:

- Measuring Range 0 to 14 pH

- Resolution 0.01 pH

- Accuracy ±0.01 pH

- Humidity ≤90% RH

- Frequency 50/60 Hz

- Application Industrial Water Treatment, Effluent Monitoring, Laboratories, Wastewater, Chemical Process Control

- Response Time ≤10 sec

- Click to View more

Online ph analyzer Product Specifications

- Continuous pH Measurement

- Automatic / Online

- pH 0 to 14

- Online pH Analyzer

- Automatic

- 2.5 kg

- 0 to 14 pH

- 0.01 pH

- 0°C - 60°C

- 4-20mA Output, RS485 Modbus

- Automatic Temperature Compensation, High/Low Alarm, Online Monitoring

- ≤10 sec

- Industrial Water Treatment, Effluent Monitoring, Laboratories, Wastewater, Chemical Process Control

- 220V AC, 50Hz

- 220V AC

- Continuous Measurement

- 50/60 Hz

- Panel Mount / Wall Mount

- 1/2 inch NPT

- ≤90% RH

- ±0.01 pH

- Digital LCD Display

Online ph analyzer Trade Information

- Western Europe, Central America, Australia, North America, Middle East, Eastern Europe, South America, Asia, Africa

Product Description

In summary, an online pH analyzer is a device that continuously monitors the pH level of a liquid in real-time. It is a critical tool in many industrial processes and wastewater treatment plants, providing valuable feedback on the pH level to help ensure quality, compliance, and efficiency.

FAQ

1. What is an online pH analyzer?

Answer: An online pH analyzer is a tool that allows users to measure and analyze the acidity of a substance or sample. It uses a digital meter to measure the pH level and display the results in real-time.

2. How accurate is an online pH analyzer?

Answer: The accuracy of an online pH analyzer depends on the type of meter used and the quality of the sample being tested. Most online pH analyzers are accurate to within 0.2 pH units.

3. What type of samples can be tested with an online pH analyzer?

Answer: An online pH analyzer can be used to test a variety of samples, including soil, water, and food samples.

4. How often should I recalibrate my online pH analyzer?

Answer: The frequency of calibration depends on the type of meter being used. Most online pH analyzers should be calibrated at least once every 6 months.

Reliable and Accurate pH Monitoring

Experience precise pH monitoring with 0.01 pH accuracy and a broad 014 pH measuring range. The analyzers quick response and automatic temperature compensation ensure reliable data even during process fluctuations, making it indispensable in critical industrial and laboratory environments where precision is essential.

Durable Construction for Demanding Conditions

Built with glass/PEEK sensors, the analyzer stands up to aggressive chemicals and harsh process conditions. Its IP65 enclosure protection and storage tolerance from -20C to +70C guarantee dependable operation and longevity, whether in wastewater treatment or chemical process control applications.

Seamless Integration and Easy Operation

This analyzer features 420mA and RS485 Modbus outputs for easy data communication with other systems. Automatic calibration and intuitive wall or panel mounting streamline setup and daily use, while relay alarm outputs offer enhanced process safety with real-time out-of-range alerts.

FAQs of Online ph analyzer:

Q: How does the auto calibration process work with the Online pH Analyzer?

A: The analyzer supports 2- or 3-point auto calibration, allowing users to calibrate the device quickly and accurately using standard buffer solutions. This process ensures measurement integrity over time with minimal manual intervention, reducing the risk of human error.Q: What applications are best suited for this Online pH Analyzer?

A: It is ideally suited for industrial water treatment, effluent monitoring, chemical process control, laboratories, and wastewater analysis. Its robust design and continuous measurement capability make it perfect for any setting requiring real-time and precise pH monitoring.Q: Where should the Online pH Analyzer be installed for optimal performance?

A: The analyzer can be wall mounted or panel mounted near the sampling point for direct, continuous readings. With IP65 enclosure protection, it is suitable for both indoor and outdoor industrial environments, provided humidity does not exceed 90% RH.Q: What are the output options for data integration and monitoring?

A: It provides both analog (420mA) and digital (RS485 Modbus) output signals, facilitating integration with various industrial control and monitoring systems. Additionally, relay alarm outputs alert operators instantly to any pH deviations outside preset thresholds.Q: How does the automatic temperature compensation benefit the user?

A: Automatic temperature compensation ensures accurate pH readings across variable sample temperatures, eliminating the need for manual adjustments and ensuring measurement consistency for process control and compliance purposes.Q: When should electrode calibration or maintenance be performed?

A: Regular calibration should be performed according to your process requirementstypically before each batch or at scheduled intervals in continuous operations. Sensor maintenance, such as cleaning, is recommended whenever measurement drift is observed or as part of routine preventive maintenance.Q: What is the advantage of using a glass/PEEK sensor in this analyzer?

A: The combination of glass and PEEK materials in the sensor provides outstanding chemical resistance and durability, making the analyzer suitable for aggressive or corrosive environments and extending its service life in demanding industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Process Analytics' category

|

Mettler-Toledo India Private Limited

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese